We’re shaping the future of intelligent raw material & construction operations

Six years ago, abaut revolutionized machine telematics with a simple idea:

Using a single, cost-effective sensor - a camera - to teach mobile machines in quarries, gravel pits and construction sites to see and understand their surroundings.

Today, that ideas has evolved into something far greater. With equipped machines operating in more than

20 countries, we see ourselves as pioneers in automated process recognition across the mining, raw materials and construction industries, redefining how sites and plants will be managed in the future.

We call it...

"Next Generation of Telematics"

Telematic Data

Intelligent Machines

Level 1:

OEM-Integration

Level 2:

abaut Basic

Level 3:

abaut Vision

Level 4:

abaut Supervison

Status data of mobile machinery

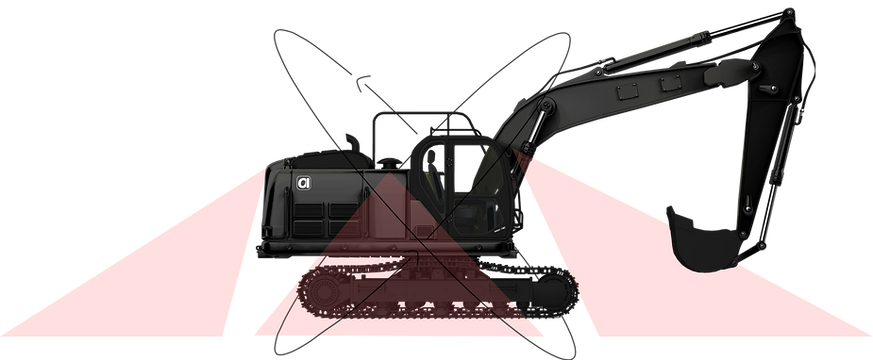

Process information through motion detection

Assistance systems powered by motion pattern detection & computer vision

The electronic brain for mobile machinery

The development of data-driven control for construction and raw material operations under one roof

By working closely with our hardware partners and develop everything in house - from algorithms to software & AI - we unlock powerful synergies on the way to creating the future operating system for the raw materials and construction industry.

.png)

Developed and designed for both small and large sites and for teams of every size across your organization

Quarry manager

With abaut, quarry managers receive fully automated, near real-time insights into mass flow and operational processes. This not only reduces costs by eliminating manual work steps, but also drives significant efficiency and productivity gains - powered by advanced process analytics and data-driven optimization recommendations.

"

Thanks to the abaut system, manual data collection for mass flow information is now a thing of the past!

Roland Hochwartner / Quarry manager at Baumit GmbH Austria

Stay up to date and discover what`s shaping abaut and the industry

_edited_edited.png)